Crane Components

Technically and economically, the high-quality components from STAHL CraneSystems rank in the premium class. Matched to them: perfectly coordinated CraneKits, unvaryingly high quality and competent contact persons for all questions relating to engineering and design. Technical edge, safety and cost-effectiveness are guaranteed by the name STAHL CraneSystems.

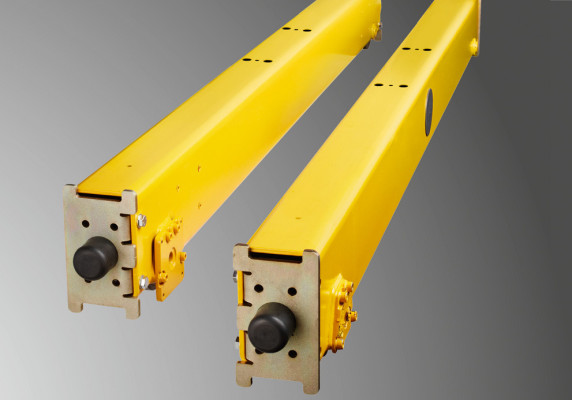

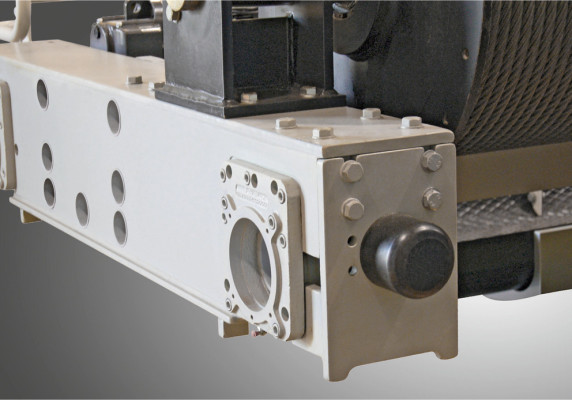

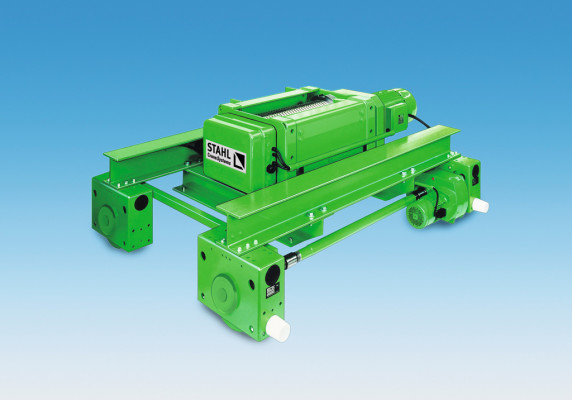

End Carriages

The robust crane endcarriages from STAHL CraneSystems provide the basis of every good crane. In this respect everything depends on accurate manufacture, high safety standards and easy erection. Our crane endcarriages originate in up to date series manufacture with a certified quality assurance system. They have proven themselves in operation thousands of times and have been improved time and again. Their compact structure makes them easy to mount on both suspension cranes and overhead travelling cranes.

- Compact and robust

- Wheels in high-quality self-lubricating

- spheroidal graphite cast iron

- Low-noise wheel drive

- Smooth starting and braking characteristics

- Simple adjustment to crane runway

- Minimum stress on crane runway girder

- Maintenance-friendly

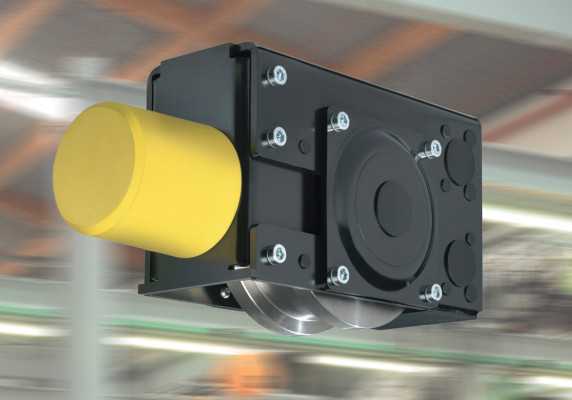

Wheel Blocks

Wheel blocks are STAHL CraneSystems’ range of products with practically unlimited potential applications: storage and retrieval machine, portal crane or stadium roof – our wheel blocks can get practically anything heavy moving. The rigorously modular system is designed for wheel loads from 5 t to 30 t. from six wheel diameters: 125, 160, 200, 250, 315 and 400 mm.

- The compact units consist of a metal housing with integrated wheel.

- Available in various assembly designs.

- Wheel loads from 5 t to 30 t in 6 frame sizes

- Multiple configurations for maximum flexibility

- Reliable drives for every requirement

- Self-lubrication ensures minimum wear

- Lifetime lubrication of roller bearings

- Maintenance-friendly

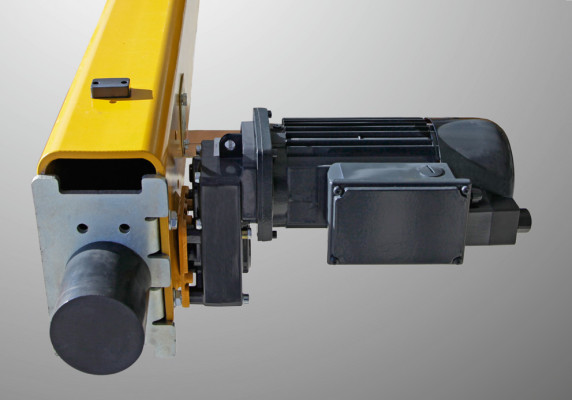

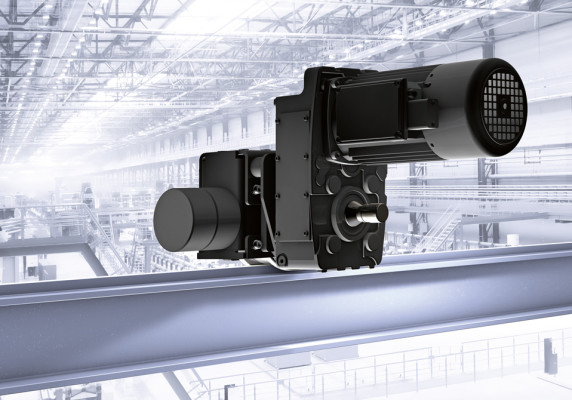

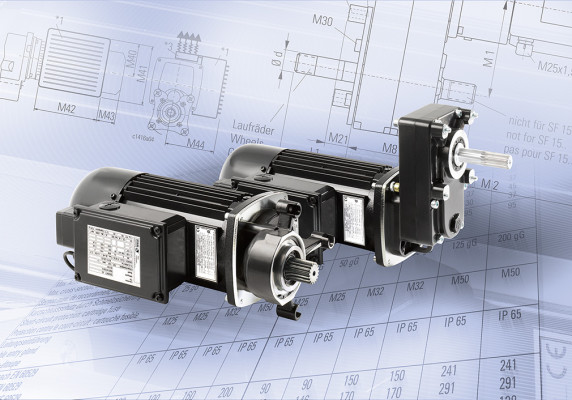

Travel Drives

Travel drives set your crane in motion. They function as crane travel drives and move wire rope hoists, chain hoists and wheel blocks. The more precisely they can be controlled, the faster and more accurately the crane operator can position his load. The integrated centrifugal mass and the low-noise gears make for particularly smooth accelerating and braking – which has a positive effect on load swing, for example. Two speeds in a ratio of 4:1 are standard.

- High duty cycle: 60 % DC

- Maintenance-free gear with lifetime lubrication

- Smooth running characteristics

- Low-noise gears

- Safe power transmission by spline shaft

- Integrated disc brake

- Integrated torque support